Manufacturing excellence depends on foundational surface preparation ensuring coating adhesion, corrosion protection, and component longevity. Professional sandblasting services establish the critical foundation upon which all subsequent finishing processes depend. When combined with comprehensive expertise from an experienced metal finishing company, manufacturers gain access to integrated solutions supporting product quality and performance objectives. Peregrine Metal Finishing specialises in delivering surface preparation and finishing processes meeting stringent industrial standards while supporting your manufacturing timelines and specifications.

How Professional Sandblasting Services Improve Coating Adhesion and Surface Quality

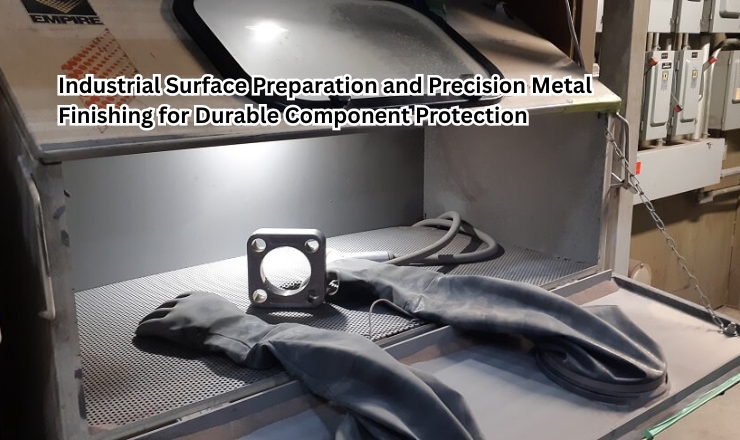

Effective sandblasting services remove contaminants, rust, and oxidised material from component surfaces, creating clean substrates supporting optimal coating performance. Industrial surfaces accumulate oils, greases, mill scale, and oxidation during manufacturing or extended storage. These contaminants create barriers preventing coatings from bonding effectively to underlying metal.

Professional sandblasting services employ precisely selected abrasive media optimised for specific material types and desired surface profiles. Steel grit, glass beads, and aluminium oxide each deliver distinct surface characteristics. Skilled operators control blasting parameters including pressure, distance, and media selection, ensuring surfaces achieve proper anchor profiles supporting paint, powder coat, and plating adhesion.

Inadequate surface preparation ranks among the leading causes of premature coating failure. When manufacturers invest in coating systems without proper surface preparation, coatings may fail through peeling, flaking, or corrosion within months. Proper sandblasting eliminates these risks by ensuring mechanical profiles enabling coatings to grip securely, withstanding temperature fluctuations, moisture exposure, and chemical contact.

Why Choosing the Right Metal Finishing Company Ensures Consistency and Long Term Performance

Selecting an experienced metal finishing company means partnering with specialists understanding material metallurgy, process chemistry, and quality standards. A comprehensive metal finishing company provides integrated solutions encompassing surface preparation, plating, passivation, and finishing processes customised to component specifications and application requirements.

Quality consistency distinguishes professional metal finishing company operations. Established finishing companies implement rigorous quality control systems including statistical process control, automated measurement, and comprehensive testing. These systematic approaches verify coating thickness, adhesion, and corrosion resistance, ensuring every component meets specifications before shipment.

Long-term component performance depends critically on proper material selection and process execution. Zinc nickel plating, black oxide, and stainless steel passivation each offer distinct corrosion protection profiles. Professional metal finishing companies assess your specific application environments, then recommend optimised finishing solutions maximising corrosion resistance while supporting cost objectives.

Environmental compliance represents another key differentiator. Leading metal finishing companies maintain state-of-the-art systems controlling water usage, air quality, and hazardous substance handling. Peregrine Metal Finishing exemplifies this commitment through water recycling systems recovering 75 percent of process water, advanced ventilation maintaining clean work environments, and full RoHS 3 compliance.

How Peregrine Metal Finishing Delivers Process Accuracy, Material Expertise, and Reliable Results

Peregrine Metal Finishing combines decades of industrial experience with cutting-edge equipment and environmental stewardship. Our integrated approach begins with professional sandblasting services preparing surfaces for optimal coating performance, then applies precise finishing processes ensuring consistent, dependable results.

Our comprehensive service portfolio encompasses zinc nickel plating for superior corrosion protection, black oxide finishing for non-reflective protective coatings, stainless steel passivation supporting biocompatibility and corrosion resistance, and shot peening enhancing fatigue resistance. This breadth enables our team to serve diverse industrial sectors from aerospace to automotive to medical device manufacturing.

As a metal finishing company committed to process accuracy, Peregrine implements rigorous monitoring and testing throughout every process stage. Our team of experienced technicians maintains equipment to exacting specifications while adhering to established metallurgical parameters. This technical discipline ensures components meet specifications consistently, supporting your manufacturing quality objectives and customer commitments.

Partnership characterises our approach. We work closely with manufacturers understanding component applications, performance requirements, and delivery schedules. This collaborative methodology ensures finishing processes support your strategic objectives while maintaining cost efficiency. Peregrine Metal Finishing stands as your trusted industrial partner, delivering surface preparation and finishing solutions you can depend on.

Conclusion

Industrial durability emerges through integrated surface preparation and precision finishing processes. Professional sandblasting services establish essential foundations, while expertise from an experienced metal finishing company delivers protective systems supporting long-term component performance. Peregrine Metal Finishing combines technical expertise, environmental responsibility, and process reliability. Contact us today to discuss your surface preparation and finishing requirements. Our team is prepared to support your manufacturing goals with solutions meeting your specifications and timelines.