Industrial Pneumatic Butterfly Valves are widely used in modern industries for regulating and controlling fluid flow. These valves are a crucial component in pipelines across various sectors such as oil and gas, chemical processing, water treatment, HVAC systems, and power plants. Their combination of reliability, durability, and automation makes them a preferred choice for engineers and plant managers worldwide.

What Are Pneumatic Butterfly Valves?

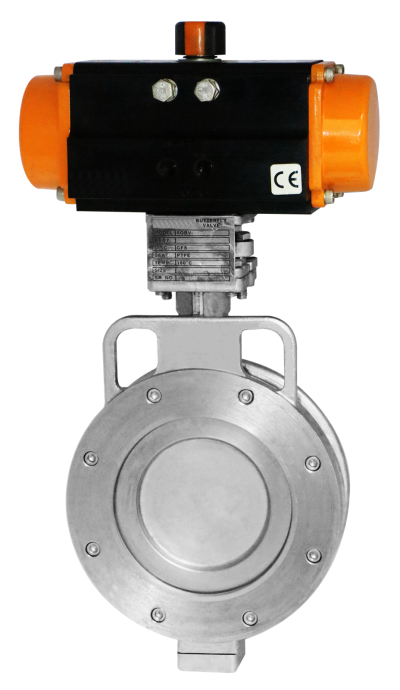

A Pneumatic Butterfly Valve is a type of quarter-turn valve operated by a pneumatic actuator. The actuator uses compressed air to open or close the valve, providing fast and precise control of fluid flow. Unlike manual valves, pneumatic actuated valves allow automation of the process, enabling remote operation and integration into modern control systems.

The valve consists of three main components:

-

Valve Body: The main structure that holds the internal components and provides connection points to the pipeline.

-

Disc or Butterfly Plate: Rotates 90 degrees to start or stop fluid flow.

-

Pneumatic Actuator: Converts air pressure into mechanical motion to control the disc.

This simple yet effective design ensures minimal flow resistance and a compact footprint, making it ideal for industries with space constraints or high-volume fluid transfer requirements.

Advantages of Pneumatic Butterfly Valves

1. Easy Installation:

Pneumatic Butterfly Valves are lightweight and compact, which simplifies installation. They can be mounted in both horizontal and vertical pipelines and require fewer supports than traditional gate or globe valves. Most industrial designs, such as wafer or lug-type valves, allow direct bolting between flanges without the need for complex welding or additional fittings.

2. Low Maintenance:

With fewer moving parts than other valves, pneumatic butterfly valves are easier to maintain. Periodic inspection and lubrication of the actuator, along with checking the sealing surface of the disc, are usually sufficient to ensure long-term performance. Unlike manual valves, there’s no need for frequent mechanical adjustments.

3. Automation-Friendly:

Pneumatic actuators provide precise control and quick operation, which is essential for automated processes. These valves can be integrated with control systems, such as SCADA or PLC, allowing real-time monitoring and remote operation. Automation reduces the need for manual intervention, improving efficiency and safety in high-pressure or hazardous applications.

4. Cost-Effective:

Compared to motorized or electric actuated valves, pneumatic butterfly valves are more economical in terms of installation, operation, and maintenance. Their simple design reduces manufacturing costs, and the lightweight structure lowers transportation and installation expenses.

5. High Reliability:

Pneumatic Butterfly Valves are highly reliable in industrial applications. The actuator ensures quick response, and the tight sealing prevents leakage. High-quality materials like stainless steel, carbon steel, or alloy ensure resistance against corrosion, abrasion, and high temperatures.

Applications of Pneumatic Butterfly Valves

Pneumatic butterfly valves are suitable for a wide range of industries:

-

Oil & Gas: For controlling crude oil, refined fuels, and natural gas pipelines.

-

Chemical Industry: Handles corrosive fluids and aggressive chemicals with precision.

-

Water & Wastewater Treatment: For flow control in water supply, treatment plants, and sewage systems.

-

Power Plants: Regulates steam, water, and cooling fluids efficiently.

-

HVAC Systems: Controls heating, ventilation, and air conditioning pipelines.

The flexibility in design and actuator options allows these valves to be tailored for specific process requirements, including high-pressure, high-temperature, or sanitary applications.

Installation Guidelines

Proper installation is critical to ensure the longevity and performance of pneumatic butterfly valves:

-

Check Compatibility: Ensure the valve size, pressure rating, and material are compatible with the pipeline and fluid.

-

Orientation: Install the valve in the correct orientation according to the flow direction marked on the valve body.

-

Flange Connection: For wafer-type valves, center the valve between flanges. For lug-type valves, bolt through the valve lugs to both flanges.

-

Avoid Stress: Do not use the valve body as a structural support. Avoid pipe stress that may distort the valve or actuator.

-

Actuator Setup: Connect the pneumatic actuator to the air supply according to the manufacturer’s instructions. Check for proper rotation and stroke limits.

Maintenance Tips

To maximize the lifespan of pneumatic butterfly valves, follow these maintenance practices:

-

Regular Inspection: Check for leaks, corrosion, or damage to the disc, seat, and actuator.

-

Lubrication: Periodically lubricate the actuator and moving components to reduce wear.

-

Tightening Bolts: Inspect flange and actuator bolts for looseness and tighten if necessary.

-

Air Supply Check: Ensure the pneumatic system maintains clean, dry, and adequate air pressure. Contaminated air can damage the actuator.

-

Seal Replacement: Replace worn-out seals to maintain leak-proof operation, especially in high-pressure or chemical applications.

Proper installation and preventive maintenance ensure that pneumatic butterfly valves deliver reliable performance for years, reducing downtime and operational costs.

Choosing the Right Pneumatic Butterfly Valve

When selecting a pneumatic butterfly valve for your project, consider the following:

-

Material Compatibility: Stainless steel, carbon steel, or alloy based on the fluid type.

-

Pressure & Temperature Rating: Ensure the valve can handle the maximum operating conditions.

-

Actuator Type: Double-acting or spring-return depending on automation needs.

-

Flow Requirements: Check the valve’s flow coefficient (Cv) to ensure it meets system requirements.

-

End Connection: Wafer, lug, or flanged type for easy integration into the pipeline.

Choosing the right valve ensures efficient operation, longer lifespan, and minimal maintenance.

Conclusion

Industrial Pneumatic Butterfly Valves are an essential solution for automated flow control in modern industries. Their combination of easy installation, low maintenance, durability, and precise automation makes them ideal for applications in oil and gas, chemical, water treatment, HVAC, and power plants.

By selecting the right material, actuator type, and proper installation practices, industries can achieve reliable, leak-proof, and long-lasting valve performance. Investing in high-quality pneumatic butterfly valves ensures smooth operations, reduces downtime, and increases overall system efficiency.