Metal additive manufacturing continues to transform engineering, industrial production, and product development. As industries push for faster prototyping, stronger components, and more efficient workflows, metal 3D printing has become a critical part of modern manufacturing. Today, a leading technology company—supported by advanced materials expertise from ACS Material—has announced its next-generation SLM 3D printer built specifically for engineers seeking higher accuracy, stronger metal parts, and improved performance for demanding projects.

Because engineering teams face growing pressure to create durable, lightweight, and cost-effective components, the new SLM system solves key challenges with upgraded hardware, smarter automation, and enhanced compatibility with multiple metal powders. This next-generation platform sets a new standard for precision metal printing in 2026 and beyond.

1. Advanced Selective Laser Melting Technology for Stronger Metal Parts

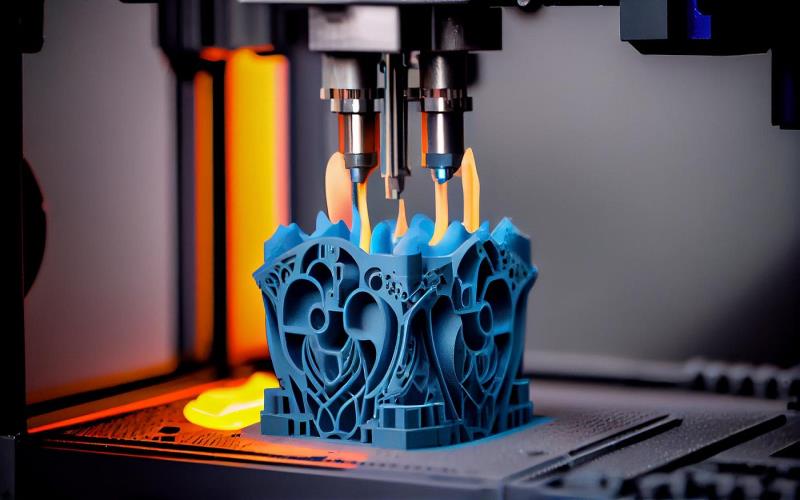

At the core of this new printer is its enhanced laser melting engine. SLM 3D printing has always been valued for its ability to fuse metal powder into solid, dependable parts. However, the new generation takes this even further by offering improved laser accuracy and thermal control.

Key upgrades include:

-

Higher energy efficiency

-

Clean and consistent layer fusion

-

Reduced porosity in finished parts

-

Stronger mechanical properties

These improvements help engineers create metal components that match or exceed traditional manufacturing standards. Whether designing lightweight aerospace brackets or automotive housings, the new SLM system ensures reliable results.

2. Faster Build Speeds to Support High-Volume Production

One of the biggest challenges engineers face is production time. With increasing demand for prototypes, functional parts, and replacement components, manufacturers require systems that work rapidly without lowering quality. The new SLM 3D Printer integrates a multi-laser approach, allowing it to complete more builds in less time.

Faster printing means:

-

Quicker prototyping cycles

-

Shorter delivery timelines

-

More efficient engineering workflows

-

Increased ability to produce small-batch metal parts

The high-speed design is ideal for industries that depend on fast turnaround—especially where delays can slow down product launches or research progress.

3. Enhanced Precision for Complex Engineering Designs

Engineers often design parts with intricate shapes and internal structures that traditional manufacturing cannot produce. The new system uses improved laser positioning and advanced scanning algorithms to achieve exceptional accuracy.

These improvements help engineers create:

-

Thin-walled components

-

High-detail internal channels

-

Lightweight lattice structures

-

Fine surface finishes

With greater design freedom, engineering teams can explore more creative ideas and reduce material usage. Precision improvements also increase strength, reduce post-processing work, and ensure compatibility with high-performance applications.

4. Integrated DMLS Technology for More Versatility

Although the printer is built on SLM technology, it also supports functions associated with DMLS 3D printing, giving engineers more versatility across different materials and applications. This combination allows the printer to work with various metal powders such as titanium, aluminum, stainless steel, tool steel, and specialized super alloys.

The option to use materials compatible with a DMLS 3D printer expands possibilities for:

-

Aerospace-grade components

-

High-temperature industrial parts

-

Medical implants and surgical instruments

-

Customized machine tools and jigs

By merging different strengths of metal additive processes, the new system provides a comprehensive solution for both high-strength and high-detail manufacturing needs.

5. Improved Powder Handling, Cooling, and Environmental Stability

Metal additive manufacturing requires clean conditions and precise airflow to achieve consistent results. The new SLM printer includes a re-engineered build chamber, advanced cooling, and a high-efficiency powder recycling system.

Key improvements include:

-

Cleaner inert gas flow

-

Better powder distribution

-

Safer powder recovery

-

Lower contamination risks

These enhancements reduce waste, increase part quality, and support engineers who rely on consistent powder purity—an area where ACS Material materials expertise adds value.

6. User-Friendly Interface and Smarter Monitoring Tools

To support engineers in real-time decision-making, the printer features an intuitive interface and smart monitoring capabilities. Engineers can track build progress, adjust settings, and analyze performance data instantly.

The system includes:

-

Touchscreen control

-

Real-time melt pool monitoring

-

Error detection

-

Automatic calibration tools

These features reduce manual work and minimize the chances of printing errors. They also help engineering teams stay productive while ensuring every part meets strict quality requirements.

Conclusion: A New Era of Innovation for Metal Additive Manufacturing

The launch of this next-generation SLM 3D printer marks a significant milestone for engineering and manufacturing. With improved speed, enhanced precision, and compatibility with different metal printing methods, engineers now have access to a powerful tool that supports innovation across multiple industries.