In industrial environments across the UAE, electric motors are the backbone of operations—from manufacturing plants and HVAC systems to power generation and logistics facilities. The performance and longevity of these motors depend heavily on one often-overlooked factor: lubrication. Selecting the right grease is not merely a maintenance decision; it is a strategic investment in uptime, efficiency, and asset protection. This is where mobil polyrex em consistently stands out. Recognized for its exceptional thermal stability and long service life, this advanced electric motor grease has become the preferred choice for reliability-focused engineers and maintenance professionals.

What Makes Electric Motor Grease So Critical?

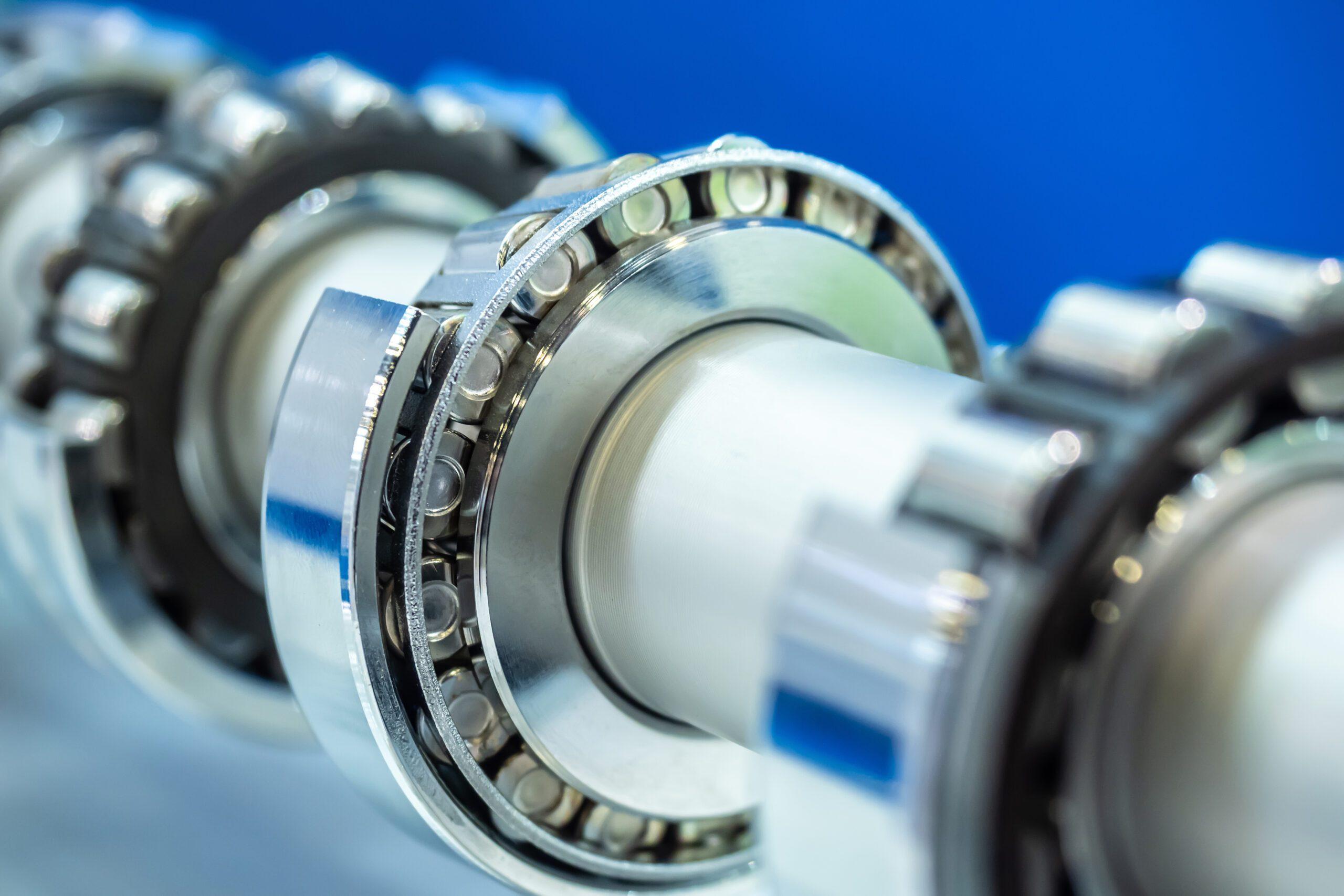

Electric motor bearings typically operate under high speeds, elevated temperatures, and continuous loads. According to industry studies, bearing-related failures account for nearly 40% of electric motor breakdowns, often due to lubricant degradation or incompatibility. A high-quality grease must therefore resist oxidation, maintain consistency over time, and protect against wear and corrosion—especially in the demanding climatic conditions of the UAE, where ambient temperatures can exceed 45°C.

The Engineering Excellence Behind Mobil Polyrex EM

Developed by ExxonMobil, Mobil Polyrex EM is a premium polyurea-based grease specifically engineered for electric motor bearings. Unlike conventional lithium-based greases, polyurea formulations offer superior oxidation resistance and inherent long-life performance without the need for heavy additive packages.

Key formulation highlights include:

- Advanced polyurea thickener for exceptional thermal stability

- High-quality mineral base oils for consistent lubrication

- Low oil separation to ensure bearing cleanliness

This combination enables motors to run cooler and more efficiently over extended periods.

Proven Performance in High-Temperature Applications

One of the defining advantages of mobil polyrex em is its ability to perform reliably at sustained operating temperatures up to 160°C, with short-term tolerance even higher. Independent laboratory testing shows significantly lower oxidation rates compared to standard electric motor greases, translating into longer relubrication intervals and reduced maintenance frequency.

For UAE industries operating in steel plants, cement factories, and large-scale HVAC systems, this thermal resilience directly supports operational continuity and cost control.

Extended Grease Life Means Lower Maintenance Costs

Frequent regreasing not only increases labor costs but also raises the risk of over-lubrication—a common cause of bearing overheating. Mobil Polyrex EM is designed for long grease life, often lasting two to three times longer than conventional alternatives under similar conditions. Maintenance teams report fewer shutdowns, reduced grease consumption, and improved bearing cleanliness, all of which contribute to a lower total cost of ownership.

Compatibility and Versatility Across Industries

Another reason mobil polyrex em is widely adopted is its compatibility with a broad range of electric motor designs and bearing materials. It is commonly used in:

- Electric motors in manufacturing plants

- Fans and blowers in commercial HVAC systems

- Pumps and conveyors in logistics and ports

- Sealed-for-life bearings in industrial equipment

This versatility simplifies lubricant standardization for facilities managers overseeing multiple sites across the UAE.

Supporting Sustainability and Reliability Goals

With growing emphasis on energy efficiency and sustainability in the UAE’s industrial sector, lubricant selection plays a supporting role. Reduced friction, lower operating temperatures, and extended service intervals help minimize energy losses and waste generation. By reducing unplanned downtime, mobil polyrex em also supports reliability-centered maintenance strategies aligned with international best practices.

Conclusion: Invest in Reliability with Mobil Polyrex EM

When electric motor reliability is non-negotiable, cutting corners on lubrication is not an option. Mobil Polyrex EM has earned its reputation as the gold standard for electric motor grease through proven performance, extended service life, and exceptional thermal stability. For UAE industries seeking to optimize maintenance costs while maximizing equipment uptime, this grease delivers measurable value.