In the modern world, industrial infrastructure, construction, and power distribution cannot compromise durability for safety. With fast expansion and growth in industries, demands have increased to make the electrical systems more reliable and capable of withstanding extreme environmental conditions, mechanical stress, and continuous operational loads. Armoured cable, as per Armoured Cable Manufacturers, is one of the most robust and versatile options among the different varieties of electrical cables for heavy-duty applications.

What is it about them that makes them so indispensable? Let’s dive deep into the structure, benefits, and key reasons armoured cables are a cornerstone in powering today’s toughest environments.

What are armoured cables?

The armoured cable is a type of electrical cable that is additionally fitted with an extra metal layer for protection so as to protect the inner conductors from physical damage. This metallic armour is fabricated mainly from galvanized steel wire or tape, or of aluminum, which acts to provide a robust mechanical barrier to enable the cable to bear tough conditions without compromising performance or safety.

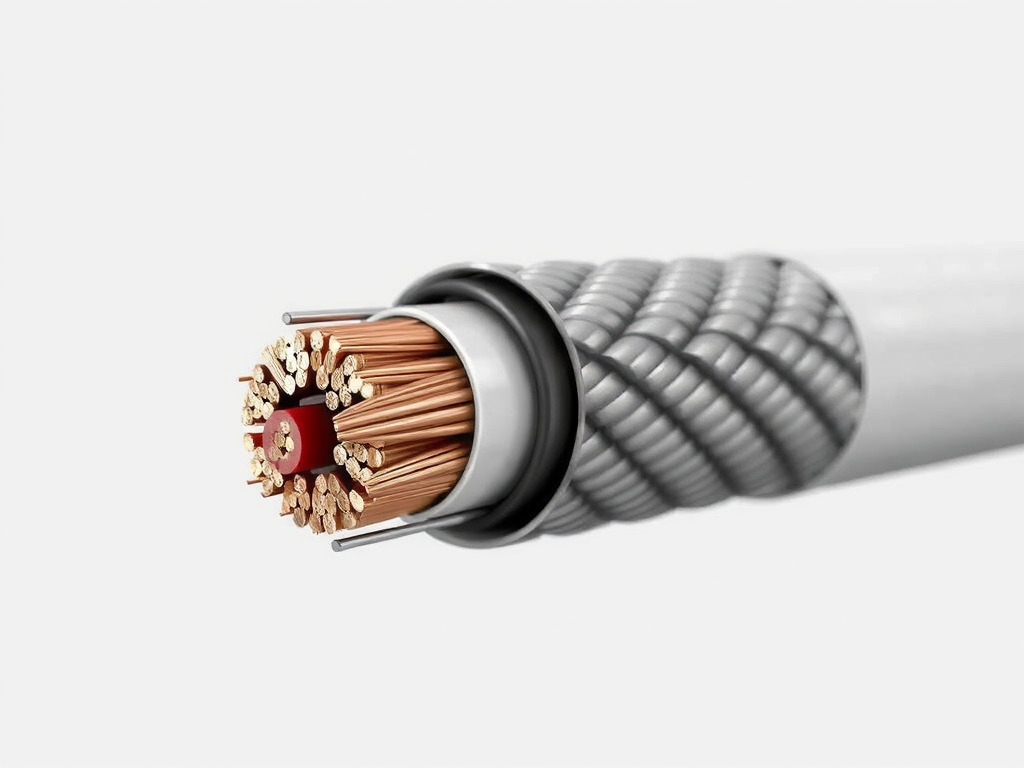

Armoured cables normally contain several major layers:

- Conductors are made either of copper or aluminum and they carry the electric current.

- Insulation: An insulation of insulating material like XLPE or PVC is present on each conductor to avoid short circuits.

- Inner Sheath Provides a bedding layer for the armour and maintains the positions of the insulated cores.

- Armour Layer: The Armour Layer refers to a metallic layer for protection against mechanical stress, crushing, and impact.

- Outer Sheath: This is the final protective coating that is usually of a material like PVC or polyethylene, resistant to moisture, chemicals, and UV radiation.

The layered constructions ensure that armoured cables supply electricity both efficiently and sustainably and maintain their reliability even in very demanding settings.

Types of Armoured Cables

A number of varieties of armoured cables, depending upon the application and environment, are in use in the industry. The most common ones include:

- SWA cable: This is used in power networks, especially in underground systems and outdoor installations that provide very good mechanical protection.

- AWA Cable: Primarily used on single-core cables to avoid magnetic interference, aluminum does not produce any magnetic fields like steel.

- STA-Steel Tape Armoured Cable: Mainly used for low voltage purposes with special consideration towards sites needing flexibility.

- Copper Armoured Cables: It has good conductivity and great tensile strength for heavy electrical leads.

Each type has been manufactured in order to balance its flexibility, strength, and conductivity according to the demands of the environment in which it will serve.

Why Armoured Cables Are Indispensable in Heavy-Duty Applications

Outstanding Mechanical Protection

In heavy-duty environments, like those at construction sites, mining zones, and industrial plants, cables are very prone to physical damage. Sharp objects and heavy machinery with continuous movements can easily destroy regular cables, which is costly, either in terms of time wasted or even danger to safety.

Armoured cables work to avoid this risk by offering increased protection. The steel or aluminum armor provides excellent resistance against crushing forces, abrasion, and the impacts caused by accidents. In fact, even under rough handling conditions, power delivery will remain consistent.

Enhanced Durability and Life Expectancy

In harsh environments, cables are threatened by moisture, oil, chemicals, and temperature fluctuations. The outer sheath of an armoured cable is usually manufactured from high-quality material, often PVC or polyethylene, which will protect the cable against corrosion and deterioration due to chemicals. Along with metallic armour, such layers ensure a service life far in excess of those of non-armoured cables.

This, of course, means lower maintenance costs and fewer replacements, but this advantage becomes quite important in industrial or outdoor applications due to the inaccessibility of cables.

Suitable for Underground and Outdoor Usage

Armoured cables are preferred for underground installations because such cables may be subjected to all types of soil pressures, rocks, and water. The armour layer against such external pressure prevents damage, while the sheath prevents moisture ingress.

They can support direct burial and exposure to weather elements without the loss of efficiency in outdoor environments, including but not limited to street lighting systems, wind farms, and solar installations. Their resistance to rodents and environmental wear makes them ideal for both temporary and permanent setups.

Excellent load-bearing capability

These include industries like manufacturing, oil & gas, and heavy engineering that require cables that should be able to carry huge electrical loads effectively. Armoured cables, due to their strong conductor and insulation, can function without heating up or voltage drops when high currents flow through them. When stability is maintained, machinery, lighting, and other important systems can operate smoothly and safely by being able to handle heavy electrical loads.

Safety and Compliance

Electrical safety is always the leading cause for concern in any industrial setup. Armoured cables are designed to meet several international standards in terms of mechanical and electrical performance. The layered design ensures very minimal chances of electric shock, fire hazards, and system failure. Besides, in case of accidental damage to the outer sheath, the metallic armour may serve as an earth continuity conductor in some cable designs and thus provide an extra layer of protection against electrical faults.

Resistance to Environmental and Chemical Stress

From the petrochemical industry to mining sites, armoured cables face different harsh conditions such as oil spills, corrosive chemicals, high humidity, and even UV radiation. Strong armour and weather-resistant sheathing materials ensure continuous operation in such conditions. Their resistance to wear by chemicals and extreme temperatures, both high and low, makes them indispensable for the industrial sectors dealing in areas that have inclement weather or dangerous conditions.

Conclusion

Built to Withstand the Toughest Challenges Armoured cables have time and again proved themselves as the backbone of reliable power distribution in industries where performance and safety entwine with durability. Robust in construction, these cables can withstand harsh conditions-be that underground pressure, mechanical impact, or chemical exposure-and still manage to provide consistent performance.

Armoured cables represent the very principle of “strength with purpose,” whether that be in construction, power networks, or renewable energy projects. They offer protection not only to the electrical circuits inside but also to the continuity of the operation in the systems they serve. In sum, an investment in armoured cables is not a technical decision but a commitment to safety, durability, and performance that ensures that your power infrastructure stands strong at all times.

Also Read: Why Are 33 kV Underground Cables Essential for Modern Power Distribution Systems?